Since cannabis pre-rolls remain the most popular retail products, manufacturers are turning to automation to meet demand and enhance product quality. Choosing the right cannabis pre-roll machine is a significant decision, as this equipment represents a major investment and can determine whether production scales efficiently or becomes a costly bottleneck. From filling technology to financing options, understanding what to prioritize helps ensure your purchase supports both current production needs and future growth.

Pre-Roll Filling Technique

The most important factor to consider when buying a pre-roll machine is the method of filling. Not every system can similarly process cannabis flower and the instrument used has a direct influence on the consistency, cleaning and downtime. Feed-screw or auger systems used in the traditional systems are good with dry powders, but have difficulty with the sticky and resinous nature of cannabis flowers. Such arrangements tend to create a sloppy operation and cleaning between the strains process and eventually lower productivity.

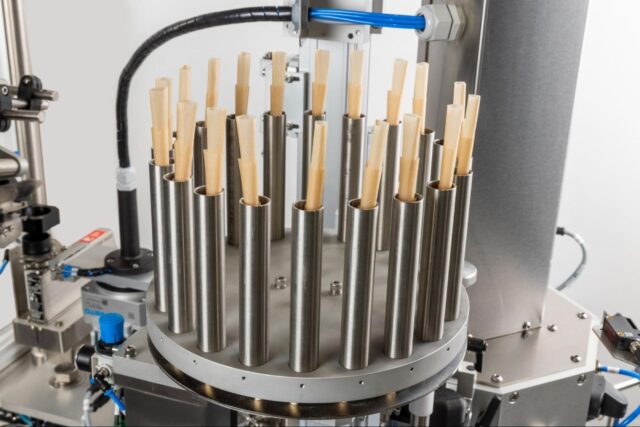

The improved machines are based on the scales and rotating tumblers that allow weighing and distributing the material more accurately. This approach gives uniform fill weights, reduces cleaning downtimes and enables producers to change batches easily. Vibration-based packing is also prevented by such systems and this can lead to inconsistency since the heavy trichomes tend to settle unequally and result in trichomes varying in terms of their potency and density as the run progresses.

Final Product Quality

The products needed should be full-fledged and market-ready products and not semi-finished cones that are produced by a pre-roll machine. Other machines have operators manually twist, cut or finish the joints after filling; and much of the benefit of automation is nullified. Preferably, the machine must carry out all the requisite procedures, i.e. filling, closing or twisting, without human intervention.

Automated finishing not only makes the production faster but also makes the presentation and quality of the smoke uniform. Even density and closed ends lead to uniform combustion and fewer customer complaints which is necessary in terms of brand reputation and regulation in controlled markets.

Reject Rate

Even the good machines have a few rejects at the highest level hence it is imperative to know the reject rate. The low reject rate will imply fewer rejectable pre-rolls and less wastage, which will maximise output and profitability. Quality systems also have reject-stations that automatically discard poor quality units thus eliminating the need for manual inspection.

In consideration of machines, inquire of manufacturers how they determine percentages of rejects, and what percentages represent completed, ready-to-sell pre-rolls. A low realistic reject rate gives assurance of the reliability of the machine and quality products all the time.

Financing Options

Most operations involve automatic pre-roll machines which entail a huge capital outlay. Luckily, with the availability of flexible financing systems, automation is achievable without disabling initial expenses. Several suppliers offer leasing arrangements, financing agreements, or out-of-pocket arrangements depending on various financial limits and expansion plans.

By scoring financing terms and machine characteristics, it is possible to match your financing with the business goals. Financing may also involve support in maintenance or consulting and this can also help reduce risk and also make adoption smooth. New manufacturers in automation are served well in support services that involve training, optimization and service.